| Max. Sheet Size |

1060 x 750mm |

41.7” x 29.5” |

| Min. Sheet Size |

450 x 390mm |

17.7” x 15.4” |

| |

|

|

| Stock Range |

Die cutting 0.2-1.5mm |

|

| |

Stamping 150-500gsm |

|

| |

|

|

| Max. Die cutting Size |

1040 x 730mm |

41” x 29” |

| Inside Chase Size |

1120 x 760mm |

44” x 30” |

| Rule Height |

23.8mm |

0.937” |

| Standard platen distance |

32.3+0.1mm |

1.272” |

| Min. Gripper Margin |

4mm |

0.158” |

| Max. Feeding Pile Height |

1350mm |

53” |

| Max. Delivery Pile Height |

1100mm |

43.3” |

| Max. Stamping Size |

1020 x 720mm |

40.2”x28.4” |

| Max. Speed |

7500 sph |

|

| Max. Stamping Speed |

7000 sph |

|

| Max. Hologram Stamping Speed |

6500 sph |

|

| Foil Advancing Shafts |

6 |

|

| Heat Zones |

12 |

|

| Max. Foil Advance |

720mm |

28.4” |

| Max. Foil Roll Diameter |

210mm |

8.3” |

| Foil Core Diameter |

25 or 76mm |

1” or 3” |

| Min. Foil Width |

15mm |

0.59” |

| Heating Capacity |

25kw |

|

| Total Power |

42kw |

|

| Dimensions |

6000 x 6000 x 2450mm |

19.7’ x 19.7’ x 8’ |

| Weight |

20000kg |

44000 lbs |

| |

|

|

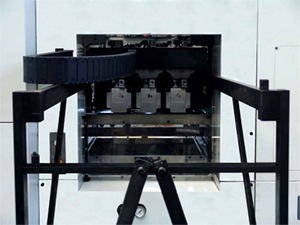

Foil unit pushed

out for stripping |

Foil unit pushed

in for foil stamping |

|

| |

| Features: |

Efficiency:

- High speed

- Quick changeover of about 10 minutes between stamping

and die cutting/stripping.

- Simple operation made possible by the Control System which

provides comprehensive automatic background calculation,

complete graphic interface and step by step work guide.

Flexibility:

- Modularized foil unwinding device is capable of foil

stamping and hologram stamping.

- Creasing, embossing, die cutting, stripping, foil stamping

and hologram stamping can all be done in one machine.

- 8 independent foil feeding in two directions: 6 longitudinal,

2 transversal (optional)

High Performance:

- IPC offers excellent performance in anti-interference,

compatibility, stability and multi-task running. Highly

capable motion control board supports various operation

system and software programming. PCI slot is expandable.

- Mabeg feeder is capable of smooth feeding for wide ranges

of stock..

- Rail support for fast job changeover of foil stamping

and die cutting.

- Two directional micro-adjustment on the cutting plate

is convenient for make-ready.

- Foil guide and telescopic foil loading support make foil

loading simple and easy.

- Thermo control system provides accurate temperature setting,

pre-heating and temperature holding in each zone.

- Pressure system assures exact pressure setting.

- AIO foil control system is capable of various types of

stamping including regular foil stamping, holographic stamping,

and holographic/foil stamping.

- New foil step module provides accurate automatic setting

and manual setting for the utmost foil use. Foil simulation

module provides foil feeding previews before real work.

- Any parameter (unwinding, step setting, temperature, pressure,

etc.) of a single job can be saved and managed as work logs

for restore or repeat in no time.

- The new detecting device and new control system offers

excellent hologram foil registration (optional).

- Air blower for foil separation, each nozzle adjustable,

is perfect for light paper (optional).

Foil rewinding cabinet is for clean and neat delivery of

used foil (optional).

|